No products

(Gratuit dès 90€ d'achat pour la France)

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

The house Baltayan

History

The company was created in 1936 and in 1958 Mr Henri Baltayan injected his dynamism, and above all his expertise, into the company. Continuing in his father’s footsteps, his son, Jean Baltayan, led the company into a distinctive position in the shoe-repair business, the two spearheads in his campaign being quality of work and the materials used. Carrying on the tradition, Jean Christophe Baltayan took over the company in 1997, injecting a touch of modernity whilst at the same time upholding the authenticity of a still traditional trade.

Today, 45 shoe shops in Lyon rely on these traditional shoemaking skills to provide a repair service for their customers. The company was approved by Paraboots in 1993 and clients flocked in, not only from the Rhône Alpes region but also from Geneva, Rome, Monaco, New York…

Products

The leathers are tanned in troughs by a traditional method over a 12 month-period using purely vegetable tannins.

The bottom leather, a living material, is selected on a side-by-side basis from the suppliers. The leather used by Baltayan comes from Bavaria and in fact the cattle, subjected to the wild climatic conditions in this region, produce a practically impermeable, exceptionally high quality leather.

All the other leathers used to produce the small leather goods, the heel grips, the insoles etc come from the best vegetal tanning companies.

The rubbers used are also of the highest quality. They do not split, do not stain and do not slip. Particular attention is given to their sturdiness and appearance.

Methods

Distinctive features of the BALTAYAN method (a few examples ... )

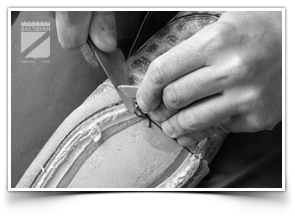

{ Soles and half soles

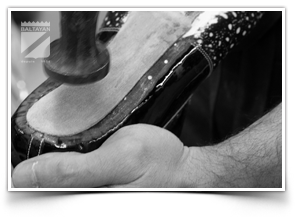

The soles and half soles are “cemented” to the shoe.

If these were merely stitched on, there would be double the amount of holes on the welt each time they were re-soled. Cementing, a traditional method, requires great technical skill to ensure that the sole does not become unstuck. The method has been improved by Baltayan and we should point out that all employees have signed a confidentiality agreement with the company. Here we see that not only are the Baltayan employees shoe makers, they are also inventors.

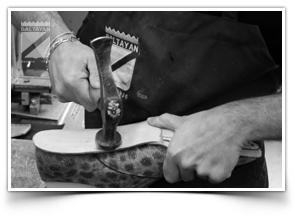

{ Leather heels with a rubber corner

Baltayan is the only company to affix leather “toplifts” with a corner in polyurethane shore 97. The sturdiness and aesthetic appearance are what make the difference.

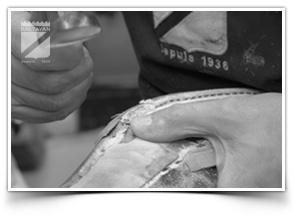

{ Heel grips

The difference produced by the Baltayan product can be seen in the complete change to the inside back of the shoe when the latter is ripped – yet another skill which has been perfected by the Baltayans. A demanding, delicate, precision task. Thus, neither the size nor the comfort of the shoe is changed.